Excitement About Tx Tees

Excitement About Tx Tees

Blog Article

The Buzz on Tx Tees

Table of ContentsNot known Details About Tx Tees Not known Details About Tx Tees The Best Strategy To Use For Tx TeesThe Tx Tees StatementsThe Ultimate Guide To Tx TeesGet This Report on Tx Tees

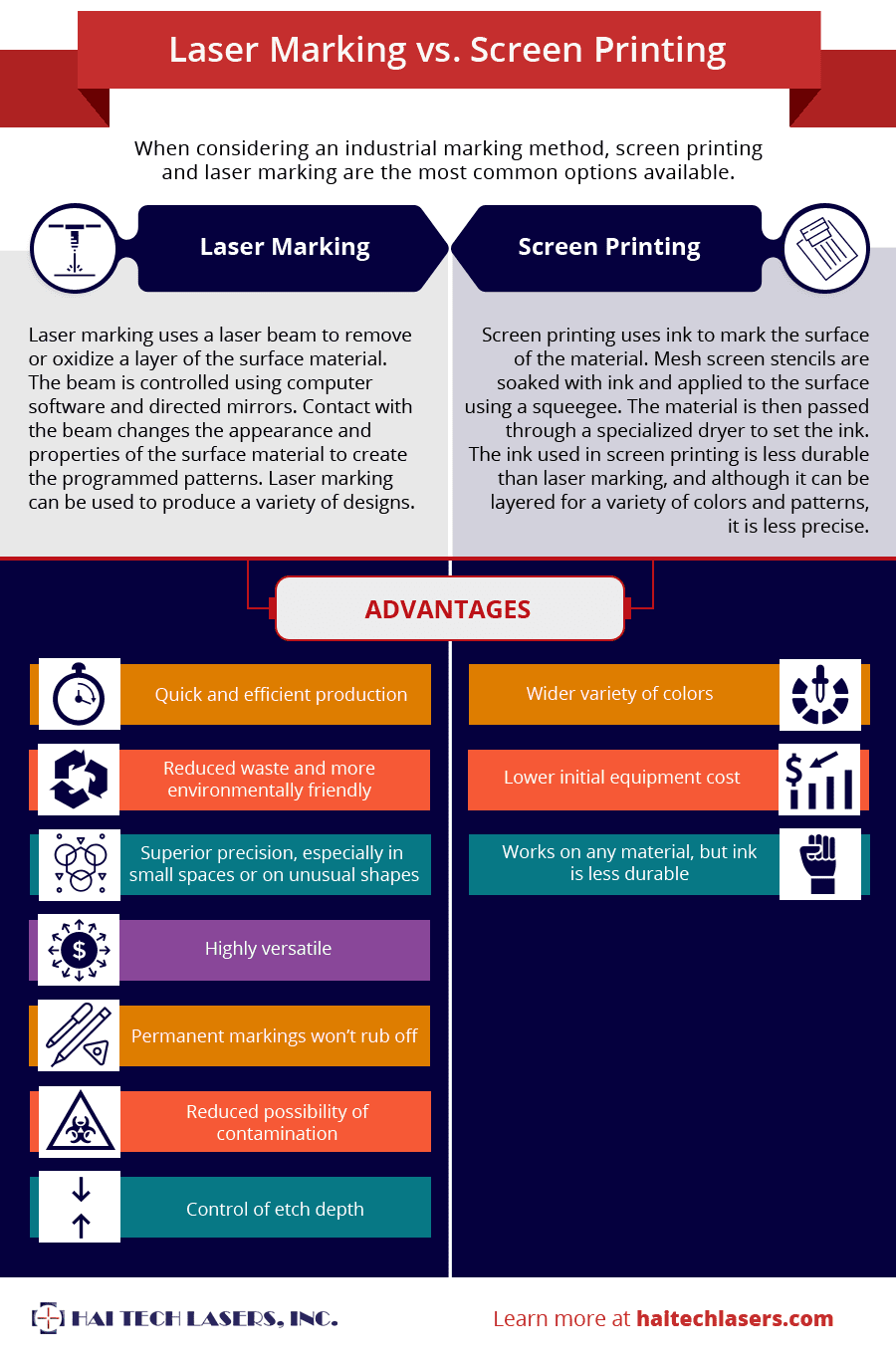

The paper is really expensive and can only be utilized as soon as. Once it's published on, it needs to be disposed of - screen printing shop. - The initial purchase cost is less than the ahead of time investment of DTG printers- You can print multi-color designs one screen at once rather than having to print each shade independently like DTG printingDisplay printers merely prepare their screen then start printing until they run out of product or ink.- There is a wide variety of seasoned screen printers all over the world, which can be useful for novices. - It's a slower process - screen printers typically have to wait on the ink to dry before they can print the next color- Display printers call for hand-operated labor, so there's a greater discovering contour and it takes longer to produce a top quality style- Display printing isn't as accurate as DTG printing, so you might obtain some "blood loss" of shades from one component of the picture onto one more if not done correctly.

However, as opposed to using display mesh as display printers do, dye sublimation printers use laser technology to move your photos onto garments or paper - https://www.easel.ly/browserEasel/14454940. A warmth process moves the dye from its solid-state directly right into the gas stage which consequently integrates it onto fabric substrates when they are quickly warmed to heats under high stress

Some Of Tx Tees

Sublimation printing is green. It makes use of less water than screenprinting, and because it doesn't involve using damaging solvents, it's risk-free for all sorts of clothing. The dye sublimation inks are likewise odor-free when treated, unlike screen printers that utilize harmful chemicals throughout the display printing process that leave an undesirable odor.

They also conserve money on pricey devices like exposure systems because color sublimation printers don't call for a UV exposure unit or a flash treatment oven that is typically made use of in screen printing. What is straight to garment printing (DTG Printing)? DTG printing is a digital screenprinting procedure that prints straight onto textile utilizing specialized inkjet printers.

DTG printing offers lots of benefits over standard screenprinting, including the ability to print photo quality pictures, better color vibrancy, and the capability to print styles on darker textiles. DTG printers work by heating up the fabric ink until it transforms right into a gas. The gas then penetrates the textile, bonding with the fibers to produce a permanent print.

The 4-Minute Rule for Tx Tees

The screen is reusable and can be used often times prior to requiring to be changed. When contrasting prices on which printing procedure to use, screen printing is typically the most prominent choice. With display printing's popularity comes its drawbacks - generally in the cost of prints and configuration time included.

While screen printing can frequently generate better results, it also takes 3x longer for each print contrasted to DTG. This suggests that display printers are frequently resting at their presses waiting on tasks to come in before they service them. With display printers only being able to produce 6-12 items per hour relying on intricacy, can accumulate rapidly and become a more expensive option than DTG printing.

With no arrangement fees, DTG printers are a wonderful choice for small companies and private consumers who wish to print a couple of t-shirts without investing a lot of cash. Additionally, there is no minimal order quantity, so print stores with these digital printers can create one t shirt each time with no service charges.

The Tx Tees PDFs

Painting the stencil onto the mesh using 'screen blockers' such as glue or lacquer. Designs made using the screen printing technique might make use of simply one color of ink, or a number of.

The ink or paint additionally hinges on layers on the surface of the fabric or paper, which offers the print a pleasingly tactile top quality. The method is also favoured because it permits the printer to quickly reproduce a layout several times. Because the very same stencil can be made use of to duplicate a design time and again, it's really beneficial for creating numerous copies of the very same garment or accessory.

When performed utilizing professional tools by a skilled printer, it's additionally possible to develop elaborate multicoloured layouts. While the complexity of the procedure does imply there's a restriction to the number of colours the printer can make use of, it does permit even more intense colouring than is possible to attain with digital printing alone.

To begin, the printer takes the design they want to develop on the finished item, and publishes it out onto a transparent acetate movie. This will certainly be utilized to develop the stencil. Next, the printer will certainly pick a mesh display to suit the complexity of the design, and the appearance of the fabric being published.

Get This Report on Tx Tees

The acetate sheet including the layout is after that laid onto the emulsion-coated screen, and find more information the whole thing is subjected to an extremely brilliant light. The light sets the solution, so the components of the display which are covered by the layout remain in liquid form. If the final design is going to include more than one colour, then a separate screen must be used to apply each layer of ink.

After the screen has been exposed for a set time, the areas of the display not covered by the layout will certainly have transformed hard. Any kind of unhardened solution is after that meticulously washed away. This leaves a clear imprint of the layout on the display for the ink to go through. The display is then dried, and the printer will make any kind of essential touch-ups or corrections to make the imprint as exact as feasible to the initial style.

The display is after that put on the printing press. The item or garment being published is put down flat onto the printing board, below the display. There are a number of various presses, consisting of manual and automated styles, yet most modern-day business printers will certainly utilize an automatic rotating carousel printer, as this permits a number of different displays to function at once.

Some Known Details About Tx Tees

The display is decreased down onto the printing board. Ink is included in the leading end of the screen, and a squeegee is made use of to pull the ink along the complete size of the screen. This presses the ink with the open locations of the stencil, inscribing the design on the product below.

To obtain a tidy, sharp print, a screen printer requires to have the right devices for the job. Here, we'll chat regarding every piece of display printing devices, including what function they offer throughout the printing process. While it is feasible to screen print with just a mesh display and a squeegee, a lot of printers prefer to make use of a press, as it enables them to print great deals of products much more successfully.

Report this page